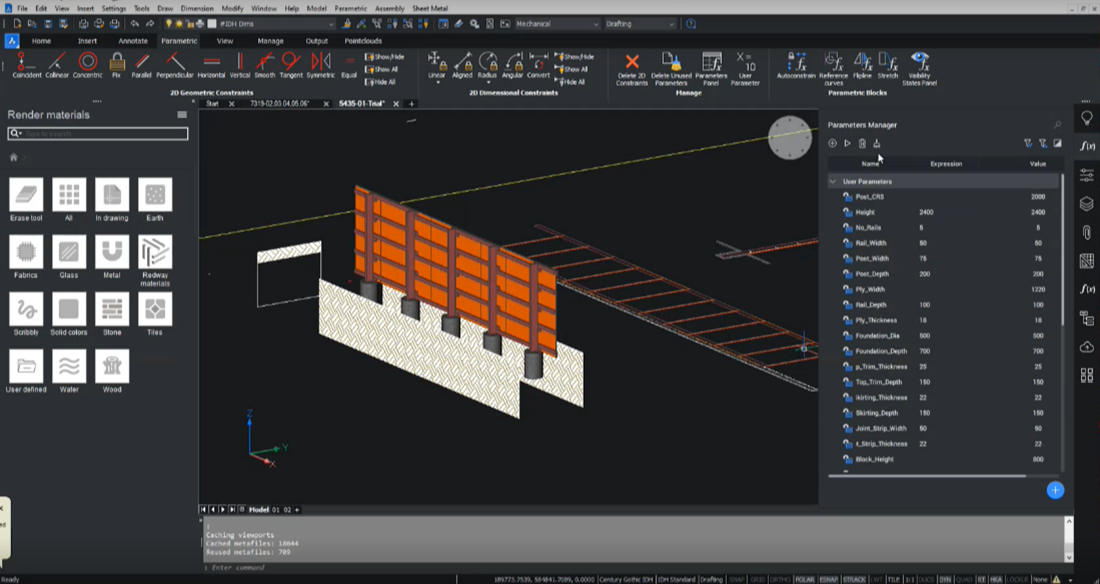

IDH Ltd migrated to BricsCAD® and their team quickly got to work using its powerful design tools and commands such as Parametric Manager panel.

With seamless 2D/3D DWG interoperability, the company easily adopted and adapted to BricsCAD’s familiar DWG platform.

Independent Design House (IDH) Ltd is an international engineering-design consultancy which offers services for innovative and professional designs of temporary works and comprehensive civil and structural engineering.

The Challenge

Reduce CAD cost, add speed and power

Like most engineering companies, IDH watches the business’ operating costs closely. With an increase in the company’s legacy-CAD costs, the management team set out to reduce their CAD cost with a better value, high-performing DWG design solution.

The Solution

Productivity boosted with one click

The team soon discovered BricsCAD’s highly productive tools with faster modeling capability. Carl James, a Design Engineer at IDH, confirmed, “I would never go back after using BricsCAD!”

Carl is one of 40 engineers at the company who has reduced the time it takes them to deliver project work after transitioning to BricsCAD.

He works within a team specializing in temporary work designs, and one of his design responsibilities is hoardings for construction sites.

With his previous software, Carl would typically work out the design parameters from calculations using MathCAD based on the customers’ specifications and site-specific parameters such as hoardings height. He then designed these aspects in 2D, and even when adapting the line work of a templated design, this work would take hours to complete.

During a trial of BricsCAD, Carl discovered the Parametric Manager Panel, a functionality he’d never had before but was familiar with the parametric modeling process. As Carl explained the faster results:

“Overnight, I was able to cut down the time it would take to create 2D documentation of a design from 3 hours to 5 minutes.”

Using the Parametric Manager Panel, Carl could quickly adapt his model. He could change the number of rails, the distance between posts, or the thickness of the wood panels within seconds. This then automatically generates the drawings the client needs in the drawing view.

Carl James: “Rather than having to redraw on multiple views of a 2D drawing, our documents are created instantly from the rapidly updated model. We did not have this capability with AutoCAD.”

Results

Easy CAD migration to a familiar DWG CAD

Carl first heard about the migration from AutoCAD® to BricsCAD® through the chatter around the office. Having not used BricsCAD before, he was curious to know how this design software would impact productivity and his work.

The company ran a trial period, where he worked in BricsCAD in tandem with their legacy software.

“There was no real learning curve,” confirmed Carl. “It is like AutoCAD; the buttons were in the same place. Some of the more ‘traditional’ people did not want to change, but there was no negative feedback after the change. It was pretty seamless.”

Carl points to the success of the easy transition because IDH could run BricsCAD alongside their legacy-CAD. Running in tandem helped the team build confidence with their new design tools. And he also found Bricsys’ support portal very responsive to a couple of questions he had.

Future productivity gains

IDH’s goal is to link the Parameters Manager in BricsCAD to a design table generated from their calculation software. This will streamline their process further and remove the need for 2D drafting.

The company is also considering rolling out this approach for generating 2D documentation from their other teams, helping to improve productivity across the business.

Source: Bricsys

Tiếng Việt

Tiếng Việt