Rao ll bridge

Danish company MT Højgaard is a Scandinavian construction and civil engineering company with customers in Denmark and abroad. Its history dates back to 1918 and together with smaller construction and civil projects, it specialises in extremely large and complex construction works,infrastructure projects and the installation of offshore wind turbine foundations. In 2011, it reported revenues of 9.3 billion Danish kroner (US$1.5 billion).

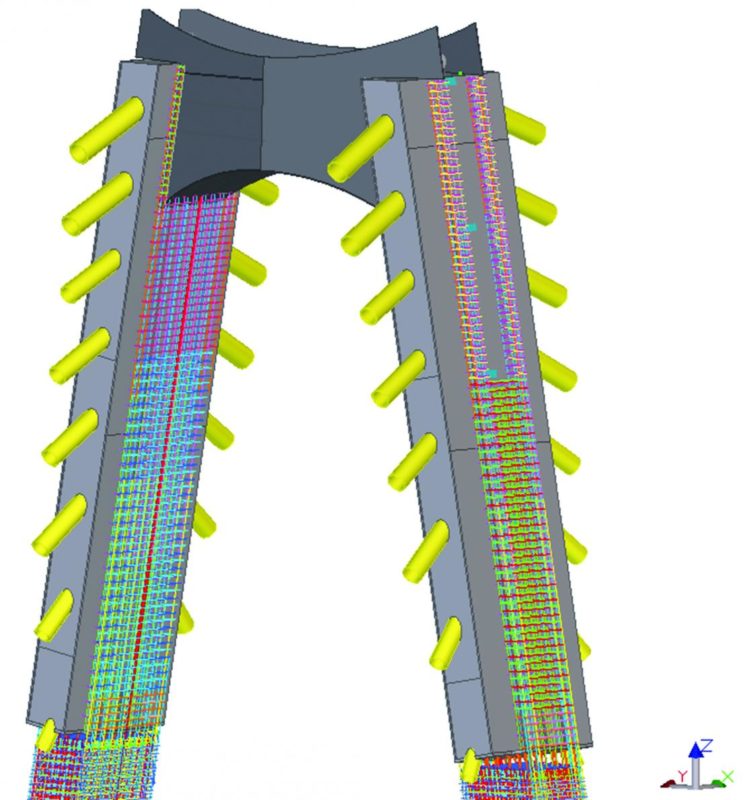

In 2009, MT Højgaard successfully bid for a project to deliver a cable-stayed bridge in Hai Phong port city, the third largest city in Vietnam. The Rao II bridge will have a span of 240 meters with one pylon carrying the main span of 120 meters and the nearest side span of 70 meters. It is a four-lane bridge with dedicated moped lanes and pavements in each direction.

The bridge will link the center of Hai Phong city with the Do Son tourist area and the coastal districts of Duong Kinh and Kien Thuy. Designed in Finland by a consortium of Finnroad Ltd and WSP ConsultingKORTES Ltd, the bridge is a significant infrastructural development and will cost about VND 661 billion (US$31.7 million) to build. The majority of the funding, about VND 600 billion, comes from Finland while the Vietnamese Government itself is investing VND 61 billion.

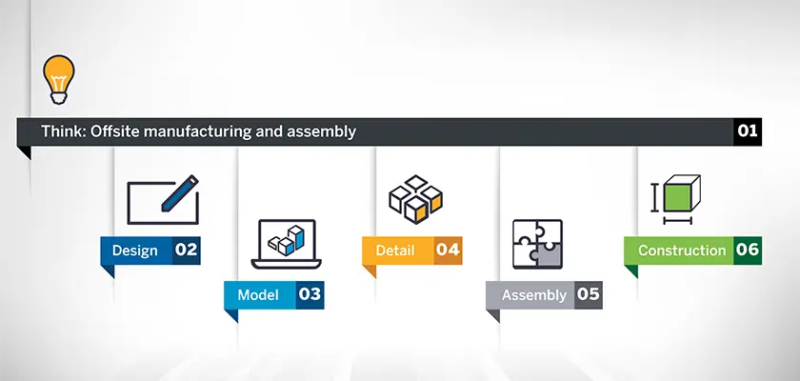

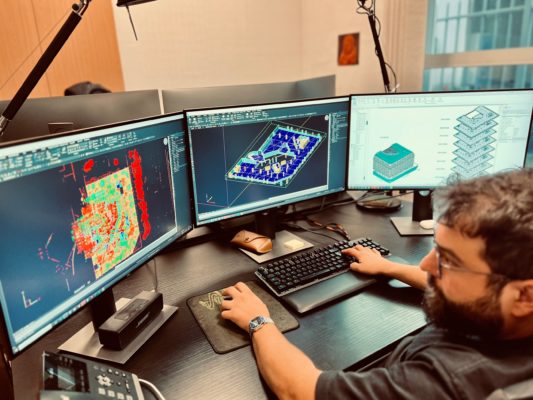

Installation and erection were designed in Denmark by MT Højgaard while the rest of the work was done by the Vietnamese subsidiary, MT Højgaard Vietnam. MT Højgaard Vietnam used Tekla for creating the working drawings for the concrete structures and for making the workshop drawings for the steel structures.

“Tekla is excellent at making workshop drawings,”said Mr Torben Rasmussen, the general director of MT Højgaard Vietnam. ”It is particularly good with complex geometry.” Tekla is also good at handling the interface between concrete and steel, he added. “If you have cables on the bridge, all the forces are in the cables. You have anchors that you have to fit into the concrete on the bridge and here Tekla is very helpful.”

For MT Højgaard Vietnam, there was no serious alternative to Tekla. “Workshop drawings in 2D or by hand is a crazy job,” said Mr Rasmussen. “It’s possible but very, very time consuming. If a company needs to make money, it is not feasible to do the workshop drawings by hand.”

Another strength of Tekla is that it is able to keep track of revisions, which was vital in this project because the project changed a number of times along the way. Tekla was able to update all associated files and keep track of the latest version.

Building Information Model at heart of project

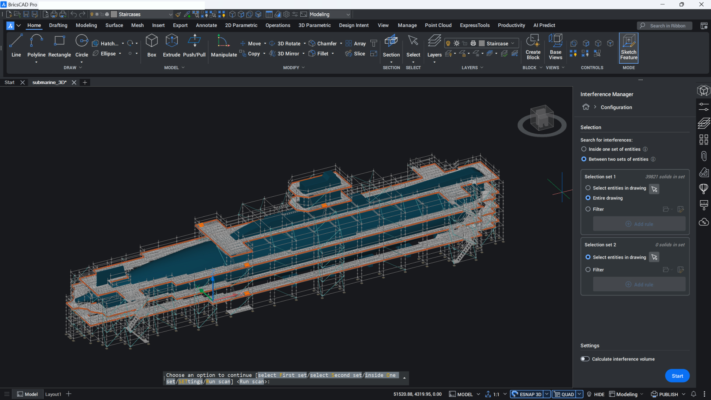

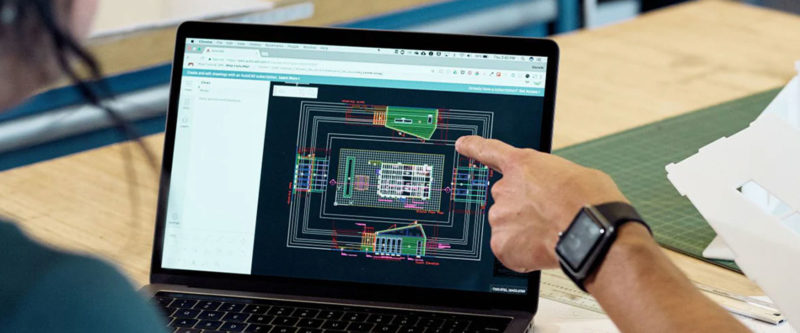

MTH also used Tekla BIM tools to provide an integrated project model so that they could create project documentation such as plans and drawings more efficiently. In addition, it gave them greater control over material procurement and installation, said Mr Peter Eagleson, a project engineer on site at the Rao II Bridge project.

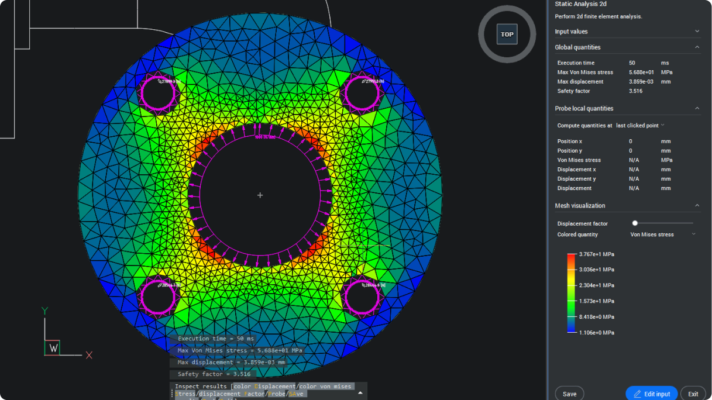

“For areas where we have complex interactions of structural steel and reinforced concrete, Tekla provides the obvious benefits of integrated modelling, clash control, and 3D visualisations,” said Mr Eagleson.

The company also relies on Tekla BIM for managing project information throughout the project’s life cycle. “During procurement and fabrication, it was great to have all the information ‘on tap’ for the creation of lists, drawings and for checking,” he said. “For installation activities, we utilised model components for finding location coordinates, and for the planning of erection sequences.”

Finally, using Tekla BIM also made communication and collaboration much easier and faster. “We conducted many online meetings with people who were in different countries,” said Ms Tran Thi Minh Thu, the Rao II Bridge team leader. “It was amazing how the long list of questions was easily understood and answered when everyone had the 3D models in front of them.”

“The 3D models saved us from having to produce sketches but much more importantly, saved time for everyone as well,” said Ms Thu.

“From a management point of view, Tekla is the best choice – especially for steel structures,” said Mr Huynh Kim Nhan, the Quality Assurance manager at MT Højgaard Vietnam “The software supplies users all the tools needed for primary design and is compatible with STAAD.Pro, a structural analysis and design computer program. It also creates the 2D drawings for manufacturing and the 3D building information model for construction as well as the visual schedule for the works on site.”

Once the drawings were completed, the steel fabricators and contractors were given the drawings. They could also view the 3D model via a web browser. This enabled the fabricators and contractors to see clearly how the different parts had to be constructed, and then assembled on site. The Rao II bridge is now well underway and is expected to be completed by 2013.

From Vietnam to Norway

Besides the Rao II Bridge, MT Højgaard Vietnam also handles the workshop drawings for a number of other projects for the parent company MT Højgaard. One of the largest projects that the team in Vietnam worked on is the Hardanger Bridge in Norway. This bridge, which will be Norway’s longest, will be built across Hardangerfjord.

The bridge, which will have two lanes plus a cycle/ footpath, will be a suspension bridge with a total length of 1,380 m. The main span is 1,310 m, which will make it 95 m longer than the Golden Gate Bridge, though shorter than the Great Belt Bridge in Denmark, which has a span of 1,624 m.

The bridge is destined to be a new Norwegian landmark with its 200 m high concrete towers and a steel construction, which will ”hover in the air” across the fjord. In total, more than 14,000 tons of steel will be used in the construction of the bridge. In fact, the suspension cables alone weigh 6,400 tons.

The bridge will replace the existing ferry and will reduce the journey time between Oslo and Bergen significantly, as well as benefiting local traffic.For this project, MT Højgaard Vietnam provided workshop drawings for the secondary steel structures like the pylon platforms, the catwalk, the tramway systems and the inspection bridge.

Tekla’s many capabilities has made it an indispensable tool for engineering companies. Thanks to Tekla BIM, companies such as MT Højgaard are able to design and build bridges that bring people and communities together.

Read more:

Tekla Structures – Rebar Detailing-Companion Detailer

Tiếng Việt

Tiếng Việt