BricsCAD® Pro won acclaim for its “stability”, “versatility”, “customizability”, and “familiarity” in the trial for a new 2D/3D CAD solution. With flexible network licensing, the evaluation team from the Paint Finishing Systems Division discusses how BricsCAD offers the right tools as their common design platform.

Taikisha Ltd is a global manufacturing business specializing in HVAC and paint-finishing systems for plants and buildings in diverse sectors such as Automotive, Aerospace, and Energy. Founded in 1913, the company has expanded internationally with the long-term vision of contributing to a sustainable society through its expertise and innovative engineering of energy, air, and water systems.

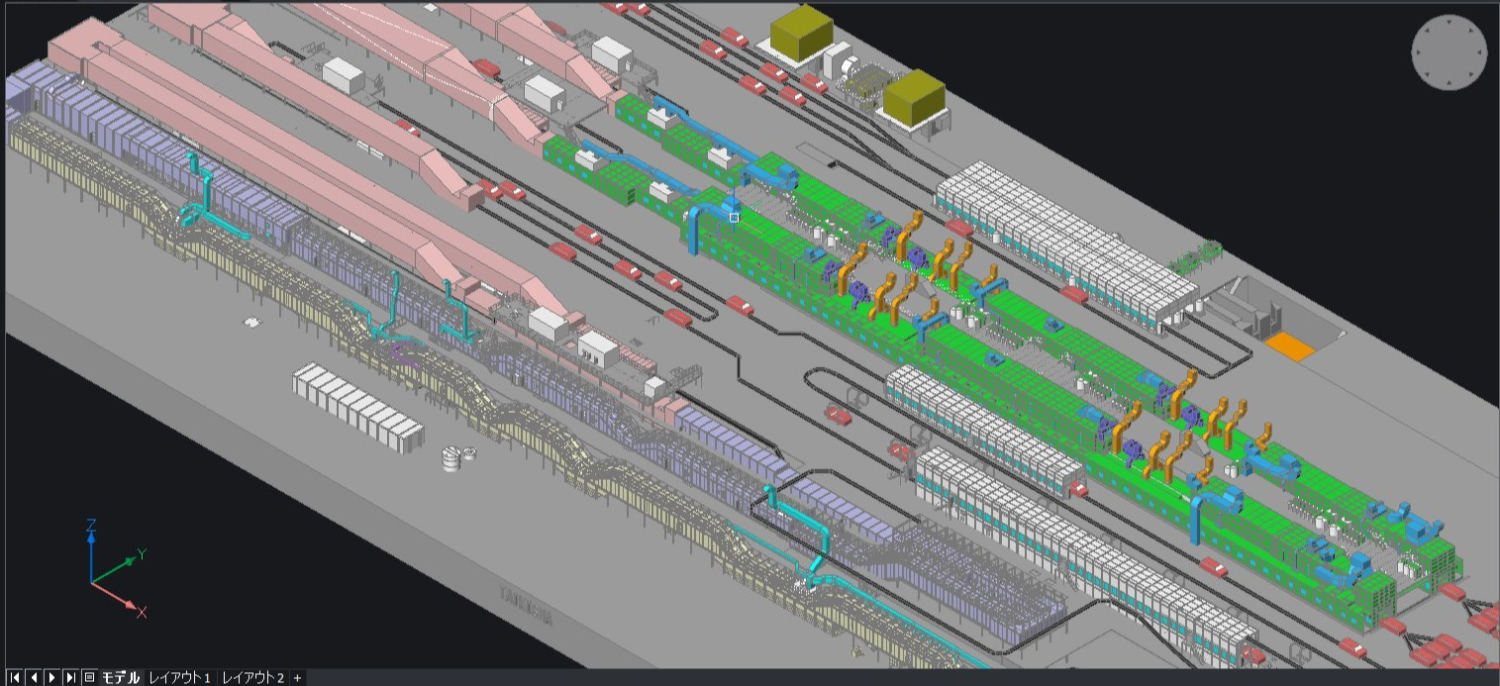

The Paint Finishing Systems Division at Taikisha Ltd. designs and constructs automobile paint-finishing systems, installed by the leading Japanese, European, and North American manufacturers worldwide.

Challenge

Automobile painting requires many stages of repeated spraying and furnace drying to cure the paint after each painting process. The coating line is a 100-meter conveyor transporting the car bodyshells through each step.

The Paint Finishing Systems Division uses 2D to design the machinery for each process and the plant’s construction equipment. Taikisha’s teams also collaborate with other contractors on 3D workflows and deliverables to construct the facilities.

Challenge #1: Network license flexibility, reduce high cost

The licensing cost of their legacy CAD software had become prohibitively expensive without the flexibility of network licensing to provide the required number of seats for the engineering design team.

Challenge #2: Highly interoperable DWG-based 2D/3D CAD

The company’s existing CAD software did not support the 3D DWG format. To reduce data-conversion work, the Paint Finishing Systems Division required an interoperable 2D/3D CAD with industry-leading fidelity.

Challenge #3: Intuitive and familiar CAD tools

For current and new design engineers joining the company, they wanted their employees to quickly adapt to CAD software with intuitively familiar tools and commands.

Solution

To tackle this challenge, the Design Management Department of the division’s Engineering Management Department began a trial study, comparing BricsCAD with their legacy software CAD and other competing CAD software.

Employees from the department and other offices participated in the verification process. Mr. Ryota Inoue of the Design Control Department at the Design and Development Headquarters, who initiated the study, explains their findings.

Stability and 2D/3D DWG compatibility

“What attracted our attention to BricsCAD was its support of the DWG format and its compatibility and versatility. In fact, we found BricsCAD to be a strong candidate because of its high stability and usability that is comparable to the competition, and the fact that it can be used in 3D as well as 2D,” confirmed Mr. Inoue.

Flexibility with network licensing

Mr. Inoue also highlighted the exceptional value of BricsCAD’s choice of perpetual and Network licenses when comparing CAD solutions:

“Competing products have become more difficult to install due to the discontinuation of perpetual and network licenses – BricsCAD supports both, and the license costs are low.

Open and highly customizable

Mr. Yukio Kanemoto of the Engineering Supervisory Department at the Paint Finishing System Division spoke about how customizations ran on BricsCAD compared to the legacy-CAD solution:

“In comparing with the existing CAD system, we focused on the customizability of the system. We are required to draw a trajectory diagram of the conveyor to ensure the product doesn’t interfere with equipment or the steel frame of the building.

Mr. Kanemoto confirmed how simple it is to customize their workflows for this layout plan:

“We had been using GUI macros to achieve this with our existing CAD system, but with BricsCAD, we found that we could create our own GUI menus through customization, which was one of the deciding factors in our decision to use BricsCAD.”

Results

Outstanding savings on a common design platform

After the studies had demonstrated BricsCAD’s capabilities, the Coating Systems Division introduced BricsCAD. Their new licensing costs are now less than a fifth of the previous CAD system, with sufficient licenses for all employees.

Mr. Kazuo Ishii, General Manager of the Design Control Department, outlined his expectations for BricsCAD by taking advantage of networked licensing:

“BricsCAD supports network licensing, and we have enough licenses available, so we intend to use BricsCAD as a common design-related platform within the company. In the past, CAD operations at our offices were highly divided. Separate tools are not efficient, so we expect to improve this situation by using BricsCAD as the common platform.”

Harnessing the talent of CAD design engineers

Mr. Ishii spoke about the need to choose a design platform to build on the knowledge and skills of his design team:

“I wanted to migrate from the existing 2D CAD system, but I felt it was difficult due to the increasing age of our operators and other factors, so I didn’t have a chance to switch. Then, I learned about BricsCAD through a subordinate and began to consider it. We were very happy with the results.”

Talking about the ease of use and training advantages for future talent, Mr. Ishii confirmed BricsCAD’s intuitive and familiar tools:

“BricsCAD is also highly compatible with the CAD software used in many engineering schools these days, and we have verified that it is just as easy to use, which will make CAD training easier for our new employees.”

Mr. Ishii also spoke about his confidence in BricsCAD to constantly innovate and support his company’s services:

“At seminars and other events, I see that BricsCAD is a product that continues to change, and I feel that it is CAD software that has great potential. I am sure it will continue to change as new features are implemented.”

Customizable for multiple 2D/3D workflows

The customization, including the automatic conveyor’s drafting, is almost complete with the help of an outside vendor. Full-scale in-house deployment is planned after the customized portion is verified, but the Design Management Department is considering further development.

Mr. Shozo Terasaka, Manager of the Design Control Dept. in the Engineering Supervisory Department, spoke of expanding BricsCAD’s solution across its affiliated companies:

“Once the customization is completed, we intend to migrate as much as possible. For example, we plan to have our affiliated companies migrate to DWG-compatible CAD, with BricsCAD in contention. After the transition, we plan to use BricsCAD for new drawings by importing data created in existing CAD systems into BricsCAD for reference.

Adding value across the business

Mr. Terasaka also highlighted how a company-wide migration to BricsCAD will add greater value by offering more capability, saying:

“As we expand the use of BricsCAD within the company and to our affiliates, we want to demonstrate the added value that only BricsCAD can provide, such as customized and unique menus and the ability to use a wide range of 3D functions.”

Source: Bricsys

Tiếng Việt

Tiếng Việt