Parametric Design

Engineers are under growing pressure to be more productive while, at the same time, structural design is becoming increasingly complex. The architectural design tools of today have expanded the possibilities for more curves and amazing structural details, all of which end up on the desktops of structural engineers who are working with smaller budgets to meet tighter deadlines. While this is especially true in bridge design, the majority of the bridge industry remains heavily reliant on drawings as primary documents. Although widely adopted, traditional 2D CAD workflows don’t solve the challenges commonly seen on projects today such as material waste, rework, RFIs, budget overruns, schedule delays, and a general lack of productivity.

These constraints are driving a growing number of structural engineers to explore parametric design and BIM-based workflows. Parametric design shifts the expression of design from geometry to the underlying logic, allowing engineers to establish rules and parameters for a model, rather than model the geometry directly. These rules operate on the input parameters, and the model is an inevitable outcome. So, when adjusting one parameter, such as the number of columns or the width of a deck, all of the model objects affected by that change are automatically updated. When parametric design is combined with the proper BIM software, the parameters can simultaneously drive information-rich BIM data beyond simple geometry.

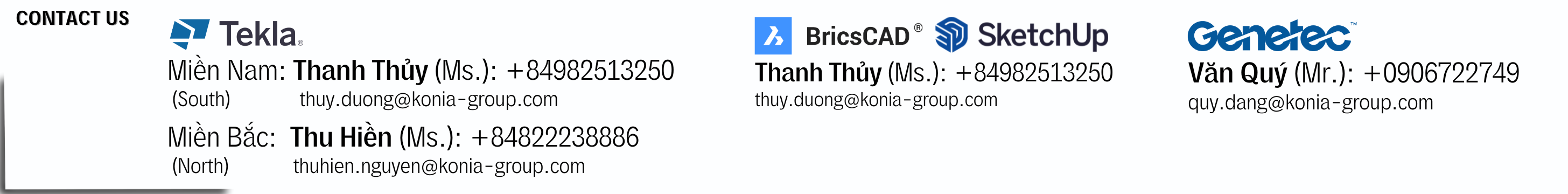

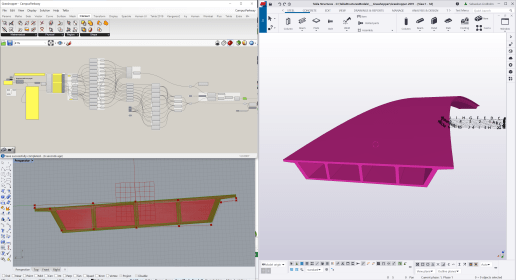

This might sound complicated, but it’s all about overcoming limitations and rapidly creating design alternatives for complex shapes. Today, structural engineers are leveraging a parametric workflow without prior knowledge of programming through direct links between BIM software and visual programming tools such as Grasshopper, a pre-installed plugin for Rhinoceros 6, a 3D computer graphics and computer-aided design (CAD) application. This allows engineers to define input parameters such as coordinates, dimensions, or curves and visually script rules that act on those parameters, generating the desired geometry or other output, which can then be applied directly to live objects using a parametric BIM software. By bringing the parametric design into a 3D parametric modeling environment, such as Tekla Structures, repetitive tasks and change updates are automated. This allows engineers to quickly, accurately and easily create a truly constructible 3D bridge model, fulfilling any Level of Development (LOD) requirement and ensuring all deliverables, including the model, drawings and material lists, are consistent.

Based on attributes the engineer defines, the effects of any change to the design are automatically populated throughout the model. Grasshopper takes the inputs, completes the calculations, and produces an output that is applied to the model. This eliminates the need to manually apply changes across the model and allows engineers to quickly generate and visualize multiple iterations of complex designs in 3D by simply adjusting the attributes. This workflow is especially beneficial when modeling structures, such as bridges, that have complex geometries and curved surfaces.

The Many Benefits of Parametric Design

Modeling with parametric design has significant benefits that improve both the design process and quality. With architects pushing the boundaries of design and projects becoming increasingly collaborative, eliminating manual processes can help structural engineers work more efficiently to meet today’s project demands. By combining parametric design with parametric modeling, engineers can:

- Accelerate work and increase accuracy. Parametric design lets engineers define logical rules describing the model and the relationships between its parts, as well as a set of parameters to drive the logic. The design tool then calculates and creates a dynamic 3D model based on that criteria that, when used with a parametric BIM software such as Tekla Structures, leads to a detailed, data-rich constructible model that contains all the information needed to build and fabricate. Eliminating manual work provides a tremendous productivity advantage by accelerating model creation and the automatic generation of the design as a whole decreases the chance for human errors that can, at worst, accumulate into costly miscalculations.

- Simplify iterations. Addressing changes is much easier with parametric modeling than with a traditional 3D model, not to mention 2D CAD. Because adjustments to the model are based on the set logic and reflected throughout the entire design, it’s possible to iterate quickly while staying within a design’s established criteria and constraints.

- Innovate with ease. When the entire design can be created, managed and iterated as a whole, there are more opportunities to optimize the design process. Parametric design and modeling provide engineers with an easy way to rapidly test and discover options for making a project more cost-effective. When a better option is discovered, the changes can be implemented quickly and with ease.

Getting Started

Trying a new approach or workflow for the first time can be intimidating. To give parametric design a try, consider these four steps:

- Be willing to try something new. This may seem obvious, but it would be easy to read the word parametric and think, “this is too complicated” or “I’m not a programmer and I don’t have time to learn something new.” If you want to give parametric design a try, the full version of Rhino Grasshopper is free to evaluate for 90 days. What’s the harm in trying it out?

- Take advantage of tutorials and instructional videos. The best way to learn is online through videos made by other structural engineers, tutorials, and forums. Some personal favorites: Grasshopper-Tekla Structures demo, Grasshopper basics and these tutorials. It’s also fun to experiment with sample Grasshopper scripts which can be found with a simple Google search.

- Experiment with a simple design. Start by experimenting with parametric data for a simple design in Grasshopper and create output objects in a parametric BIM software. It’s not necessary to jump right in and learn using a complex bridge model. For example, build a simple wireframe structure, such as a portal frame, and use the line output as centerlines for the parametric BIM objects.

- Get Organized. It’s important to know that parametric design and modeling require organization. Create notes and keep the script of parameters organized and well documented so that any project stakeholder can understand it a week, or even a month, later.

With dynamic automation, increased accuracy, rapid iterations, and more resources for the design as a whole, the benefits of parametric design are undeniable. While it can be used for any project big or small, it’s especially advantageous in complex structures with unconventional architecture. Using parametric design with constructible BIM-tools takes the modeling process to the next level and makes it possible to streamline work, create high-quality and constructible designs and deliver successful projects – totally model-based without drawings.

Contact Us:

Southern:

0965.694.591- Ms. Hồng Ngọc | Email: ngoc.vu@konia-group.com

0903.920.792- Ms. Đỗ Linh Ân | Email: an.do@konia-group.com.

Northern: 0822.238.886 – Ms. Thu Hiền |Email: thuhien.nguyen@konia-group.com

Tiếng Việt

Tiếng Việt